SECTION 10: TAILCONE: Difference between revisions

mNo edit summary |

m (→Page 10-2) |

||

| Line 8: | Line 8: | ||

== Page 10-2 == | == Page 10-2 == | ||

Step 3 - Consider also using the center line on the back of the AEX tie down as an additional reference to center the AEX to the centerline of the F-1012A bulkhead. It can be difficult to accurately center the marked lines in the exact centers of the holes as referenced in the plans. | Step 3 - Consider also using the center line on the back of the AEX tie down as an additional reference to center the AEX to the centerline of the F-1012A bulkhead. It can be difficult to accurately center the marked lines in the exact centers of the holes as referenced in the plans. | ||

- 5/28/22 I did it per the plans, drawing the two lines exactly. Now use a cleco CLAMP on the bottom (threaded end) and a wood C clamp on the top gently holding it in place while you drill the 4 holes. A little confusing in the plans it calls to drill the 3/32 out w/ a # 30 drill. Correct. It's a 3/32 hole oversize it to #30 so it will receive a -4 (4/32) rivet down line. See page 10-18 for rivet size. Drill the 4 #30 holes first and cleco as you go. Then drill the 3/16 holes also clecoing if you have 3/16 clecos. | |||

[[File:2022-05-28 15-36-10.jpg|thumb|Tie down assembly]] | |||

Step 1: 5/28/22 Taping the Tie down. Note: The hole should first be drilled out to 5/16 to receive a 3/8-16 tap. The hole is undersized by Vans. A trick a machinist taught me, put the tap in your drill press and center your piece under while turning the tap BY HAND. DON'T turn on the drill! It's just a jig to keep things straight while you start the tap. Once you get a couple turns on the tap, take it out, put in your vice and finish. | |||

[[File:Sec 10-2 Tap drill.jpg|thumb|Tap drilling]] | |||

== Page 10-4 == | == Page 10-4 == | ||

Revision as of 21:42, 28 May 2022

If you intend on installing a yaw damper as part of your autopilot package, you are encouraged to think about the mounting hardware for it while you are building the tailcone, as access is much easier NOW than later. See this page for more details: https://rv10.org/index.php?title=Yaw_Damper_Servo

Vans also sells a mounting bracket that fits in the RV-10 tailcone (https://rv10.org/index.php?title=File:Screen_Shot_2022-03-24_at_11.50.50_AM.png) that is perfect for a spot to mount additional hardware. It's much easier to install earlier in the build process than later.

Preparation

Make sure you have enough clecos. During the initial assembly, I used about 650 clecos.

Page 10-2

Step 3 - Consider also using the center line on the back of the AEX tie down as an additional reference to center the AEX to the centerline of the F-1012A bulkhead. It can be difficult to accurately center the marked lines in the exact centers of the holes as referenced in the plans.

- 5/28/22 I did it per the plans, drawing the two lines exactly. Now use a cleco CLAMP on the bottom (threaded end) and a wood C clamp on the top gently holding it in place while you drill the 4 holes. A little confusing in the plans it calls to drill the 3/32 out w/ a # 30 drill. Correct. It's a 3/32 hole oversize it to #30 so it will receive a -4 (4/32) rivet down line. See page 10-18 for rivet size. Drill the 4 #30 holes first and cleco as you go. Then drill the 3/16 holes also clecoing if you have 3/16 clecos.

Step 1: 5/28/22 Taping the Tie down. Note: The hole should first be drilled out to 5/16 to receive a 3/8-16 tap. The hole is undersized by Vans. A trick a machinist taught me, put the tap in your drill press and center your piece under while turning the tap BY HAND. DON'T turn on the drill! It's just a jig to keep things straight while you start the tap. Once you get a couple turns on the tap, take it out, put in your vice and finish.

Page 10-4

Step 1 - Double check the length and make sure you center the F-1010A on the F-1010 bulkhead to avoid any edge distance issues later on when match drilling the top deck to the longerons.

Page 10-5

Step 4 - Consider making a jig to make drawing the center line more consistent and efficient. YouTube video: https://youtu.be/yC1kzDO_Gg8?t=590

When cutting the stiffeners to length, consider making them slightly longer than Vans recommends in the instructions by approx 1/8 inch. If cut too short, you may end up with edge distance issues when match drilling the end rivet holes. The length can then be adjusted if desired after first fit up.

Page 10-13

There is a service bulletin (https://www.vansaircraft.com/wp-content/uploads/2018/03/sb18-03-30.pdf ) for the elevator stop (F-1012D). As mentioned in this YouTube build video (https://youtu.be/g5ONB4e28TI ), Van's did send the required material to create the new part with the rest of the kit (subkit #5), but did not update the plans to reflect the service bulletin.

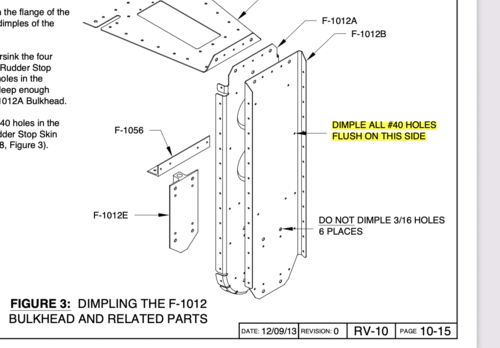

Page 10-15

Step 7 instructions only apply to the web of the F-1012B Bulkhead. Dimpling of the flanges of this part is done in step 4 on page 10-16 which instructs to not dimple the topmost hole.

Page 10-20

If working alone, you can get away with riveting the bottom skin stiffeners to the bottom skin before clecoing the side skins on.

Step 7 - The outer rivets are very hard to get to. Plans call for AN470AD4-4 rivets, but you may consider using CR3213-4-2 CherryMax rivets (confirmed with builder support that this should be okay). Measure your parts to ensure proper rivet length. You may have to modify your hand riveter to fit within the opening. YouTube video: https://youtu.be/cvwDYFGeK6s?t=614