3D-Printed Tools and Parts: Difference between revisions

Jump to navigation

Jump to search

mNo edit summary |

mNo edit summary |

||

| (10 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

See also section [[CAD_CAM_Files]] if you have a CNC machine.<br>Consider joining the [https://www.facebook.com/groups/756340465159308 3D Printed Aircraft Parts] FB group. | See also section [[CAD_CAM_Files]] if you have a CNC machine.<br>Consider joining the [https://www.facebook.com/groups/756340465159308 3D Printed Aircraft Parts] FB group. | ||

---- | |||

Warning: Depending on the filament material, 3D-printed parts may not withstand high temperatures, e.g. those encountered in an engine compartment. One example is this Cozy Mk IV airplane crash where a commercially 3D-printed air induction elbow collapsed. [https://www.msn.com/en-us/news/technology/plane-crashed-after-3d-printed-part-collapsed/ar-AA1RJalY Source]. | |||

[[File:Cozy Mk IV intake collapse.png|300x300px]] | |||

---- | |||

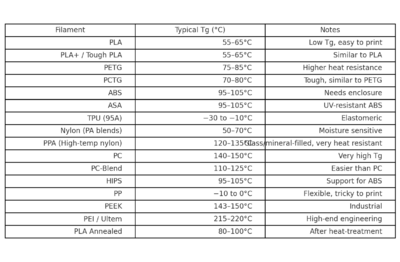

Here is a material list and their glass temperatures (caution: composed by AI):<br>[[File:Filament Tg table.png|400x400px]] | |||

---- | |||

* [https://rv10.ca/3d-printed-stuff Les Kearney's Collection of 3D printed parts for the RV-10] | * [https://rv10.ca/3d-printed-stuff Les Kearney's Collection of 3D printed parts for the RV-10] | ||

* [https://airplane.allanglen.com/2023/06/03/wing-conduit-pitot-lines/ Allan's wing conduit and pitot line bracket] | * [https://airplane.allanglen.com/2023/06/03/wing-conduit-pitot-lines/ Allan's wing conduit and pitot line bracket] | ||

| Line 22: | Line 28: | ||

* End cap for armrest<br>[[File:Screenshot 2025-02-16 at 4.25.49 PM.png|300x300px]]<br>[[File:Arm rest cap.jpg|300x300px]]<br>[[Media:Center Console - armrest endcap.stl|End Cap stl file]] | * End cap for armrest<br>[[File:Screenshot 2025-02-16 at 4.25.49 PM.png|300x300px]]<br>[[File:Arm rest cap.jpg|300x300px]]<br>[[Media:Center Console - armrest endcap.stl|End Cap stl file]] | ||

* Door hinge alignment jig. Print 2 of these and snap them to the bottom of WD-1018 in lieu of the three .125 scrap aluminum pieces for spacing (see 45-06 step #3).<br>[[File:Door Alignement Jig.jpg|300px]]<br><br>[[File:Hinge Jig In Use.jpg|300px]]<br>[[Media:Hinge Bracket Jig STL file.stl|Hinge alignment jig STL file]] | * Door hinge alignment jig. Print 2 of these and snap them to the bottom of WD-1018 in lieu of the three .125 scrap aluminum pieces for spacing (see 45-06 step #3).<br>[[File:Door Alignement Jig.jpg|300px]]<br><br>[[File:Hinge Jig In Use.jpg|300px]]<br>[[Media:Hinge Bracket Jig STL file.stl|Hinge alignment jig STL file]] | ||

* Headset hanger<br>[[File:Screenshot 2025-09-18 at 6.49.08 AM.png|300px]]<br>[[Media:Headset Hanger.stl|Headset Hanger stl file]] | * Headset hanger<br>[[File:Screenshot 2025-09-18 at 6.49.08 AM.png|300px]]<br>[[Media:Headset Hanger.stl|Headset Hanger stl file]] [[Category:Optional]] | ||

* Throttle quadrant handle<br>[[File:throttlehandle.jpg|300px]]<br>[[Media:RV-10 Throttle Handle.stl|Throttle Handle stl file]] | * Throttle quadrant handle<br>[[File:throttlehandle.jpg|300px]]<br>[[Media:RV-10 Throttle Handle.stl|Throttle Handle stl file]] | ||

* 3D-printed Tools for Beringer Wheels<br>[[File:rim_tools.jpg|300px]]<br>[[Media:Beringer 5 Tire Cone.stl|5 inch cone stl file]]<br>[[Media:Beringer 6 Tire Cone.stl|6 inch cone stl file]] | * 3D-printed Tools for Beringer Wheels<br>[[File:rim_tools.jpg|300px]]<br>[[Media:Beringer 5 Tire Cone.stl|5 inch cone stl file]]<br>[[Media:Beringer 6 Tire Cone.stl|6 inch cone stl file]] | ||

Latest revision as of 19:52, 7 December 2025

See also section CAD_CAM_Files if you have a CNC machine.

Consider joining the 3D Printed Aircraft Parts FB group.

Warning: Depending on the filament material, 3D-printed parts may not withstand high temperatures, e.g. those encountered in an engine compartment. One example is this Cozy Mk IV airplane crash where a commercially 3D-printed air induction elbow collapsed. Source.

Here is a material list and their glass temperatures (caution: composed by AI):

- Les Kearney's Collection of 3D printed parts for the RV-10

- Allan's wing conduit and pitot line bracket

- Shawn's wing conduit and pitot line bracket

- FB thread on printing wing conduit brackets

- Oil Cap with center hole for engine dehumidifier

- Conduit holder with variable tilt angle

- Front RV-10 vent plug

- Glareshield strut compass holder (stl file), credit Igor, VAF member supik

- FB thread on avionics fan controller enclosure

Fan controller enclosure V1.stl

Fan controller lid V1.stl - Current Sensor mount by Rodrigo

- Current Sensor mount for AWG 2 cable by Martin. Uses 3 cable ties to hold the parts and cable together.

Onshape Project: current_sensor_mount

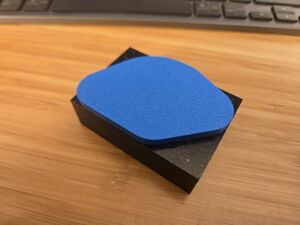

- End cap for armrest

End Cap stl file - Door hinge alignment jig. Print 2 of these and snap them to the bottom of WD-1018 in lieu of the three .125 scrap aluminum pieces for spacing (see 45-06 step #3).

Hinge alignment jig STL file - Headset hanger

Headset Hanger stl file - Throttle quadrant handle

Throttle Handle stl file - 3D-printed Tools for Beringer Wheels

5 inch cone stl file

6 inch cone stl file - Template for trimming the flap torque tube bushings

Flap bushing template.stl